Aluminum Foundry key ideas explained in a friendly article

Wiki Article

A Deep Study Steel Foundries: Crucial Information and Industry Trends

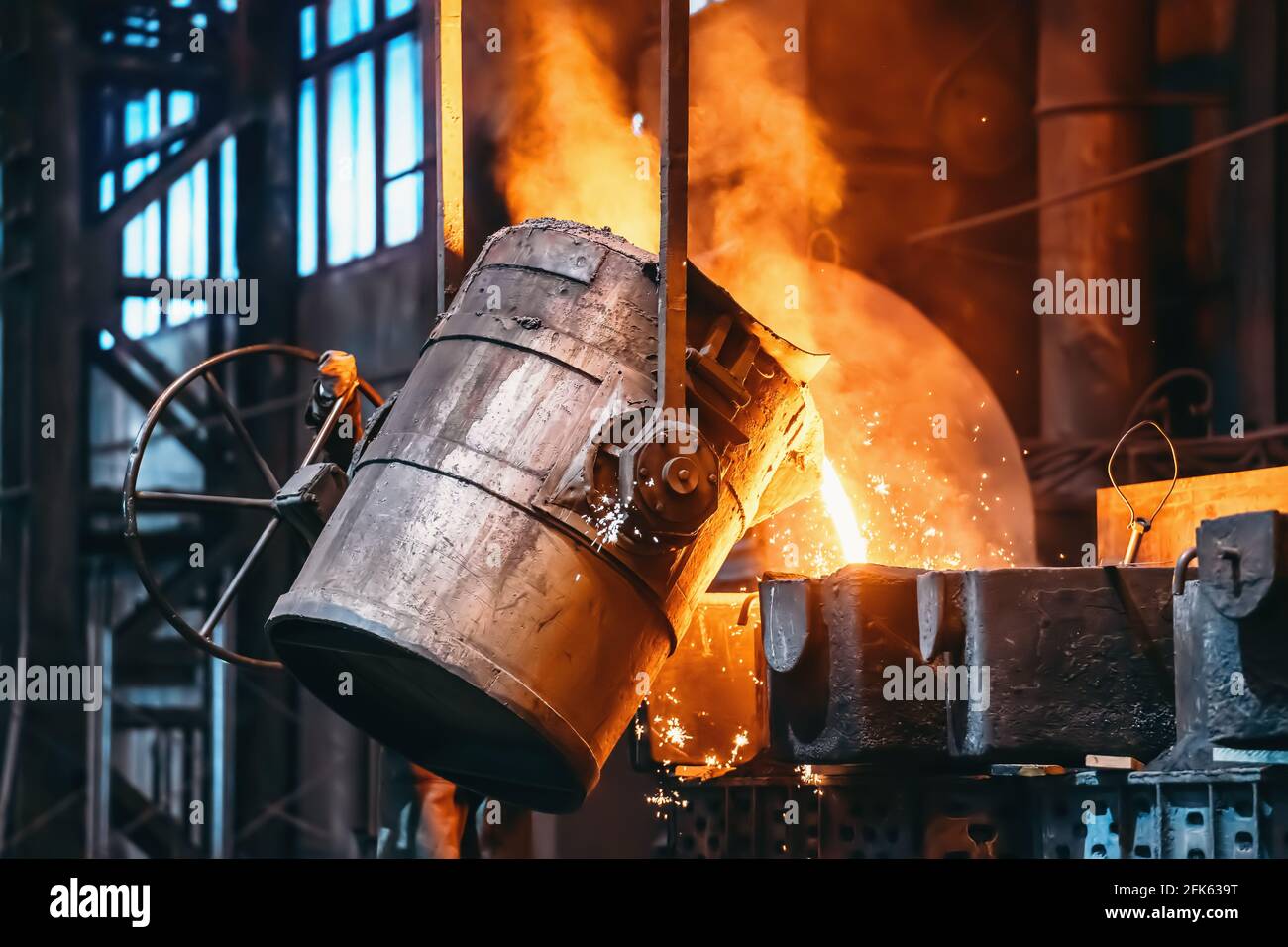

Steel factories play a vital function in the manufacturing field, changing resources into vital elements. The processes entailed, from melting to quality assurance, are intricate and need precision. Recent advancements are improving the market, introducing automation and sustainability techniques. Challenges linger, especially regarding labor and material prices. Comprehending these elements is essential for grasping the existing landscape and future direction of factories. What lies ahead for this fundamental market?Recognizing the Steel Foundry Refine

The steel shop process might appear complex, it rotates around a couple of fundamental stages that change raw products into completed steel items - Aluminum Foundry. Initially, basic materials such as steel ores, scrap steel, and alloys are sourced. These products undertake melting in furnaces, reaching high temperatures to melt the steel. Once molten, the metal is poured right into mold and mildews, where it cools down and solidifies into the preferred formAdhering to solidification, the spreadings are removed from the molds, resulting in additional processing. This might consist of cutting excess product, surface area ending up, and warmth therapy to enhance buildings. Quality control evaluations are necessary throughout the process to assure that the end products satisfy needed requirements and requirements.

Trick Technologies Fueling Factory Technologies

The innovations in innovation have actually significantly influenced the metal foundry sector, driving advancements that enhance performance and item quality. Key innovations reshaping this industry include automation and robotics, which simplify procedures and decrease labor prices, enabling for accuracy in mold production and metal pouring. In addition, the fostering of 3D printing is transforming pattern manufacturing, enabling complex layouts that typical methods can not accomplish. Simulation software application has arised as a necessary device, enabling factories to predict and fix prospective casting issues prior to production, thus saving time and resources. The combination of IoT (Internet of Things) gadgets boosts surveillance and information collection, promoting real-time adjustments to processes. Finally, innovations in metallurgy, such as the growth of new alloys, are expanding the capacities of foundries to create more powerful and lighter elements. Together, these technologies are transforming the landscape of steel shops, driving them toward higher innovation and competition.The Role of Quality Assurance in Metal Spreading

Quality control plays an important function in steel spreading, making sure that each component satisfies stringent specifications and efficiency standards. This procedure includes a selection of techniques, including aesthetic assessments, dimensional dimensions, and product testing - Aluminum Foundry. Shops use top quality control personnel that monitor each phase of production, from resources selection to the final item assessmentBy utilizing innovative technologies such as non-destructive testing and automated inspection systems, metal factories can recognize problems early in the production cycle. This aggressive method reduces waste and decreases the chance of costly rework. In addition, adherence to industry requirements, such as ISO certifications, enhances a shop's dedication to top quality, boosting customer self-confidence and satisfaction.

Inevitably, reliable quality assurance not just improves the dependability and longevity of cast parts however also drives constant improvement within the foundry, fostering a culture of excellence and innovation in steel casting procedures.

Sustainability and Environmental Practices in Foundries

As metal factories progressively acknowledge their impact on the environment, a dedication to sustainability has actually ended up being vital in their functional techniques (Aluminum Foundry). Many foundries are carrying out energy-efficient modern technologies, such as electrical induction heating systems, which substantially lower greenhouse gas discharges contrasted to standard techniques. The fostering of recycled products, particularly scrap steel, has actually also gotten traction, reducing waste and saving natural depositsMoreover, water monitoring practices are being enhanced to reduce usage and protect against contamination. Many foundries are buying closed-loop systems that reuse water utilized in cooling and cleansing processes. In addition, dust and exhausts regulate technologies are being updated to ensure conformity with ecological guidelines.

Future Trends and Obstacles in the Steel Factory Market

Emerging trends in the metal shop industry highlight a shift in the direction of advanced technologies and innovative techniques aimed at improving performance and competitiveness. Automation, consisting of robotics and fabricated intelligence, is significantly taken on to Metal Foundry decrease and enhance operations labor costs. In addition, the combination of Market 4.0 innovations helps with real-time data evaluation, allowing far better decision-making and predictive upkeep.Nevertheless, obstacles continue. The industry encounters an experienced labor lack, demanding financial investment in workforce training and growth. Changing raw material prices and supply chain interruptions pose significant difficulties. Ecological policies are becoming more stringent, pushing factories to adopt lasting methods that can be costly originally however helpful long-term.

In enhancement, the need for lightweight and high-performance alloys is increasing, requiring factories to innovate their procedures and materials. Stabilizing these trends with recurring challenges will certainly be important for the future success of the steel shop industry.

Regularly Asked Concerns

What Is the Background of Metal Shops?

How Do Foundries Determine Metal Alloy Compositions?

Factories establish steel alloy make-ups via a combination of empirical testing, computer modeling, and industry standards. They examine wanted homes, application requirements, and cost-effectiveness, guaranteeing the last alloy fulfills specific efficiency requirements for intended uses.What Are one of the most Common Foundry Products Used?

One of the most common factory products consist of cast iron, light weight aluminum, brass, steel, and bronze. These materials are preferred for their toughness, resilience, and adaptability, making them suitable for various applications in manufacturing and building.How Do Factories Deal With Hazardous Waste Disposal?

Factories take care of harmful waste disposal through strict adherence to environmental laws, employing specialized control systems, reusing campaigns, and partnerships with licensed waste management firms to assure secure and certified disposal of toxic materials.What Profession Opportunities Exist in the Metal Foundry Industry?

Steel foundries play an essential role in the production sector, changing raw materials right into vital elements. The steel foundry process might appear facility, it rotates around a couple of fundamental phases that change raw products right into completed metal items. The improvements in modern technology have actually substantially affected the steel shop market, driving advancements that boost performance and product high quality. The history of steel factories dates back to old worlds, where artisans initially thawed steels to produce tools and decors. The steel foundry sector uses diverse career chances, including functions in engineering, top quality control, operations monitoring, and environmental conformity.

Report this wiki page